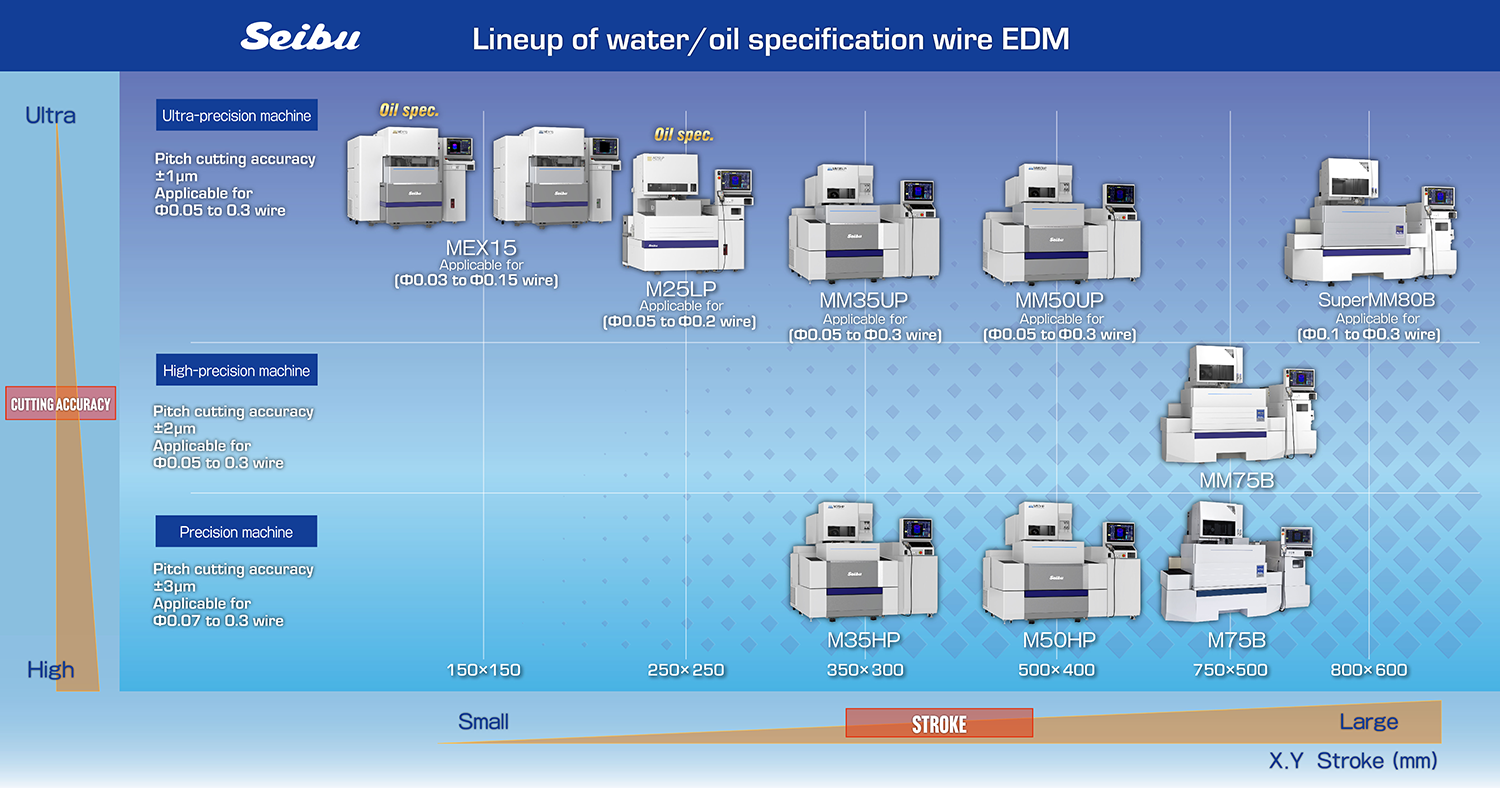

PRODUCT INTRODUCTION

Wire Electrical Discharge Machine

Wire EDM Machines for Precision Machining - mm

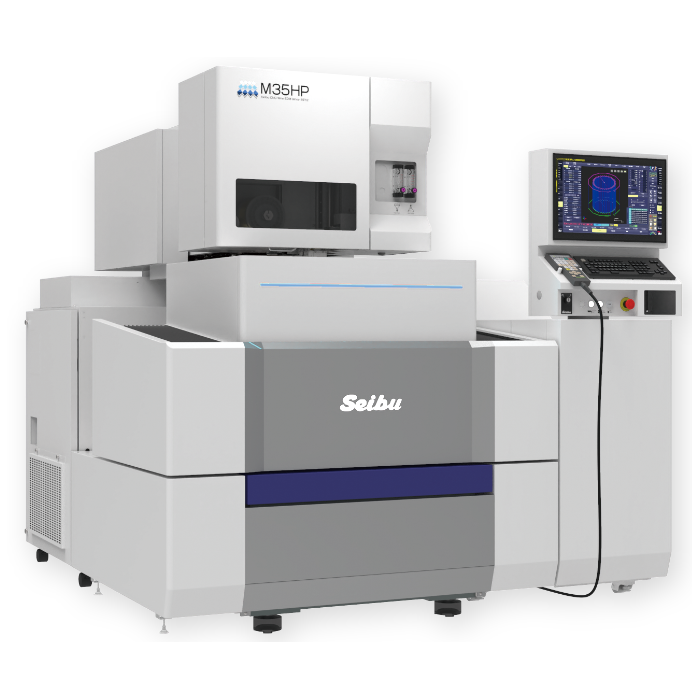

Water Specification Wire EDM

Water Specification Wire EDM

Standard type with high speed, high precision,

and advanced functions

350×300

| Standard Specifications | M35HP |

|---|---|

| Max. workpiece dimensions W×D×H |

700×630×220mm |

| Max. workpiece weight | 350kg |

| Axis travel range X×Y×Z |

350×350×230mm |

| U-V axis travel U×V |

±60× ±60mm |

| Max. taper angle | ±10°/work thickness 220mm (±45°/40mm: Option) |

| Dimensions W×D×H |

1,640×2,060×1,955mm |

| Weight | 2,900kg |

| Control device | Smart NC |

|---|---|

| Input system | MDI, Ethernet, USB |

| Display | 21.5 inch TFT multi-touch screen |

| Axis controlled | 5 axis (simultaneously 4 axis) |

| Least input increment | 0.01µm |

| Least command increment | 0.01µm |

| Program memory capacity | 1GB |

| Power Supply | MPSC-20 |

|---|---|

| Input power source | 3-phase 200V/220V±10% 11 kVA, 50/60Hz |

| Weight | 160kg |

| Filtration device | MF35 |

|---|---|

| Tank capacity | 700L |

| Filter element | 4 paper filters Φ340 ×300mm |

| Deionizer | Ion exchange resign 20L |

| Weight | 400kg |

Wire diameter : Φ0.07 to Φ0.30mm

(Φ0.25mm is standard.)

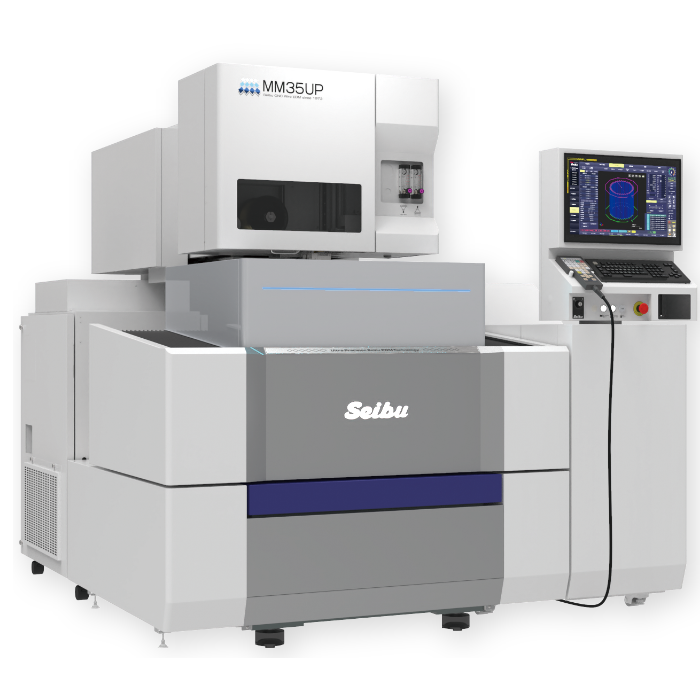

±1µm pitch accuracy is achieved to reduce the jig grinding process, which contributes to shortening delivery time in high-precision die production.

350×300

| Standard Specifications | MM35UP |

|---|---|

| Max. workpiece dimensions W×D×H |

700×630×220mm |

| Max. workpiece weight | 350kg |

| Axis travel range X×Y×Z |

350kg×300×230mm |

| U-V axis travel U×V |

±60× ±60mm |

| Max. taper angle | ±10°/work thickness 220mm (±45°/40mm: Option) |

| Dimensions W×D×H |

1,640×2,060×1,955mm |

| Weight | 2,900kg |

| Control device | Smart NC |

|---|---|

| Input system | MDI, Ethernet, USB |

| Display | 21.5 inch TFT multi-touch screen |

| Axis controlled | 5 axis (simultaneously 4 axis) |

| Least input increment | 0.01µm |

| Least command increment | 0.01µm |

| Program memory capacity | 1GB |

| Power Supply | MPSC-20 |

|---|---|

| Input power source | 3-phase 200V/220V±10% 11 kVA, 50/60Hz |

| Weight | 160kg |

| Filtration device | MF35 |

|---|---|

| Tank capacity | 184.92gal |

| Filter element | 4 paper filters Φ340 ×300mm |

| Deionizer | Ion exchange resign 20L |

| Weight | 400kg |

Wire diameter : Φ0.05 to Φ0.30mm

(Φ0.25mm is standard.)

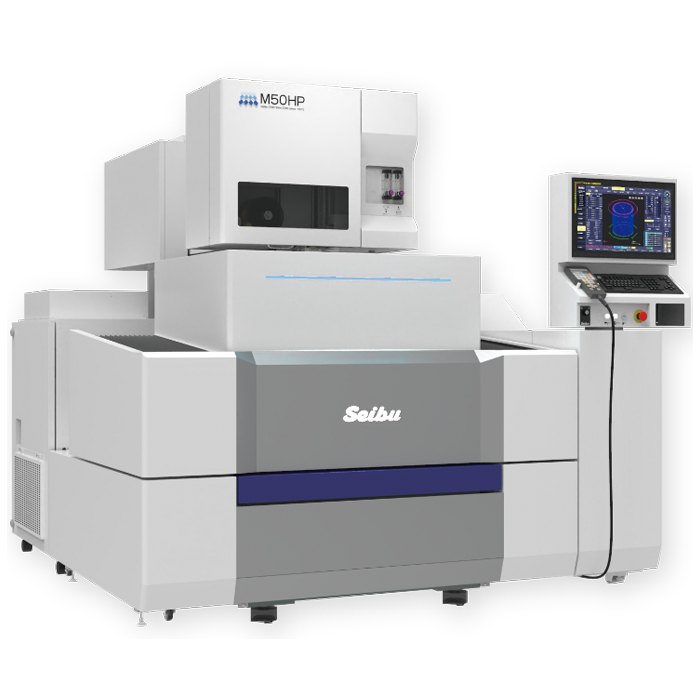

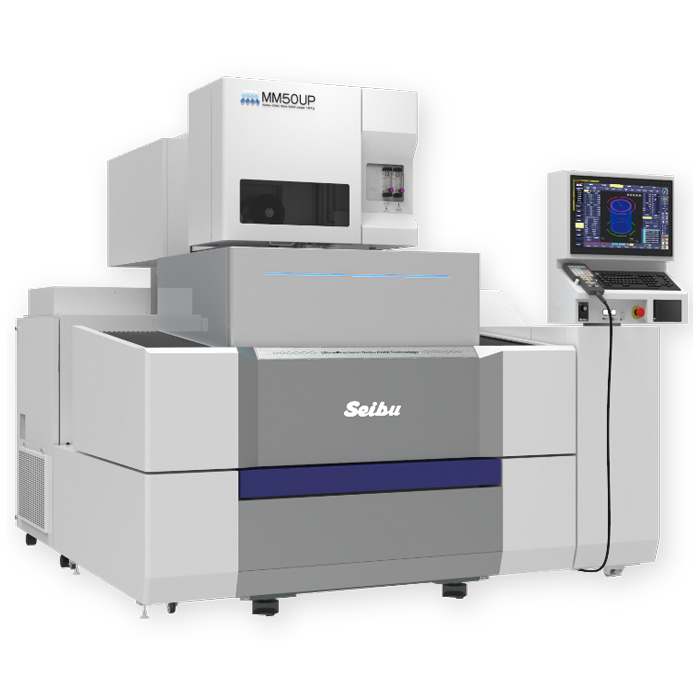

Standard type with high speed, high precision, and advanced functions

500×400

| Standard Specifications | M50HP |

|---|---|

| Max. workpiece dimensions W×D×H |

850×730×300mm |

| Max. workpiece weight | 800kg |

| Axis travel range X×Y×Z |

500×400×310mm |

| U-V axis travel U×V |

±60× ±60mm |

| Max. taper angle | ±10°/work thickness 300mm (±45°/40mm: Option) |

| Dimensions W×D×H |

1,915×2,260×2,035mm |

| Weight | 3,500kg |

| Control device | Smart NC |

|---|---|

| Input system | MDI, Ethernet, USB |

| Display | 21.5 inch TFT multi-touch screen |

| Axis controlled | 5 axis (simultaneously 4 axis) |

| Least input increment | 0.01µm |

| Least command increment | 0.01µm |

| Program memory capacity | 1GB |

| Power Supply | MPSC-20 |

|---|---|

| Input power source | 3-phase 200V/220V±10% 11 kVA, 50/60Hz |

| Weight | 160kg |

| Filtration device | MF50 |

|---|---|

| Tank capacity | 740L |

| Filter element | 4 paper filters Φ340 ×300mm |

| Deionizer | Ion exchange resign 20L |

| Weight | 430kg |

Wire diameter : Φ0.07 to Φ0.30mm

(Φ0.25mm is standard.)

±1µm pitch accuracy is achieved to reduce the jig grinding process, which contributes to shortening delivery time in high-precision die production.

500×400

| Standard Specifications | MM50HP |

|---|---|

| Max. workpiece dimensions W×D×H |

850×730×300mm |

| Max. workpiece weight | 800kg |

| Axis travel range X×Y×Z |

500×400×310mm |

| U-V axis travel U×V |

±60× ±60mm |

| Max. taper angle | ±10°/work thickness 300mm (±45°/40mm: Option) |

| Dimensions W×D×H |

1,915×2,260×2,035mm |

| Weight | 3,500kg |

| Control device | Smart NC |

|---|---|

| Input system | MDI, Ethernet, USB |

| Display | 21.5 inch TFT multi-touch screen |

| Axis controlled | 5 axis (simultaneously 4 axis) |

| Least input increment | 0.01µm |

| Least command increment | 0.01µm |

| Program memory capacity | 1GB |

| Power Supply | MPSC-20 |

|---|---|

| Input power source | 3-phase 200V/220V±10% 11 kVA, 50/60Hz |

| Weight | 160kg |

| Filtration device | MF35 |

|---|---|

| Tank capacity | 740L |

| Filter element | 4 paper filters Φ340 ×300mm |

| Deionizer | Ion exchange resign 20L |

| Weight | 430kg |

Wire diameter : Φ0.05 to Φ0.30mm

(Φ0.25mm is standard.)

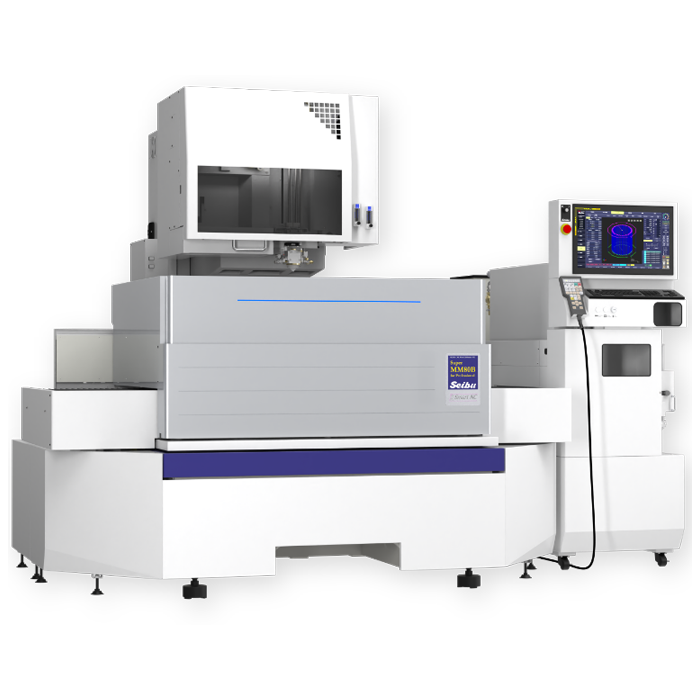

High precision, large workpiece

750×500

| Standard Specifications | MM75B | M75B |

|---|---|---|

| Max. workpiece dimensions W×D×H |

900×700×220 (270*1)mm |

900×700×250 (300*2)mm |

| Max. workpiece weight | 1,000kg | |

| Axis travel range X×Y×Z |

750×500×280mm | 750×500×310mm |

| Automatic wire feeging device | AWF-4 equipped as standard | |

| U-V axis travel U×V |

±60× ±60mm | |

| Max. taper angle | ±10°/work thickness 270mm | ±10°/work thickness 300mm |

| (±45°/40mm: Option) | ||

| Dimensions W×D×H |

2,280×2,200×2,155mm | |

| Weight | 5,100kg | |

| Control device | Smart NC |

|---|---|

| Input system | MDI, Ethernet, USB |

| Display | 21.5 inch TFT multi-touch screen |

| Axis controlled | 5 axis (simultaneously 4 axis) |

| Least input increment | 0.01µm |

| Least command increment | 0.01µm |

| Program memory capacity | 1GB |

| Power Supply | MPSC-20 |

|---|---|

| Input power source | 3-phase 200V/220V±10% 11 kVA, 50/60Hz |

| Weight | 160kg |

| Filtration device | MF1100BD |

|---|---|

| Tank capacity | 1,100L |

| Filter element | 4 paper filters Φ340 ×300mm |

| Deionizer | Ion exchange resign 20L |

| Weight | 350kg |

| Wire diameter : Φ0.25 is standard. | |

|---|---|

| MM75B | M75B |

| Φ0.05mm to 0.30mm | Φ0.07mm to 0.3mm |

| *1 Flush cutting available for work 220 to 270mm high. | *2 250 to 300mm |

Achieves an incredible pitch accuracy of ±1µm with the largest cutting area in the series

800×600

| Standard Specifications | SuperMM80B |

|---|---|

| Max. workpiece dimensions W×D×H |

1,00×800×150mm |

| Max. workpiece weight | 600kg |

| Axis travel range X×Y×Z |

800×600×230mm |

| Automatic wire feeging device | AWF-4 equipped as standard |

| U-V axis travel U×V |

±60× ±60mm |

| Max. taper angle | ±10°/work thickness 150mm (±45°/40mm: Option) |

| Dimensions W×D×H |

2,380×2,400×2,155mm |

| Weight | 6,300kg |

| Control device | Smart NC |

|---|---|

| Input system | MDI, Ethernet, USB |

| Display | 21.5 inch TFT multi-touch screen |

| Axis controlled | 5 axis (simultaneously 4 axis) |

| Least input increment | 0.01µm |

| Least command increment | 0.01µm |

| Program memory capacity | 1GB |

| Power Supply | MPSC-20 |

|---|---|

| Input power source | 3-phase 200V/220V±10% 11 kVA, 50/60Hz |

| Weight | 160kg |

| Filtration device | MF1100BD |

|---|---|

| Tank capacity | 1,100L |

| Filter element | 4 paper filters Φ340 ×300mm |

| Deionizer | Ion exchange resign 20L |

| Weight | 350kg |

Wire diameter : Φ0.10mm to Φ0.30mm

(Φ0.25mm is standard.)

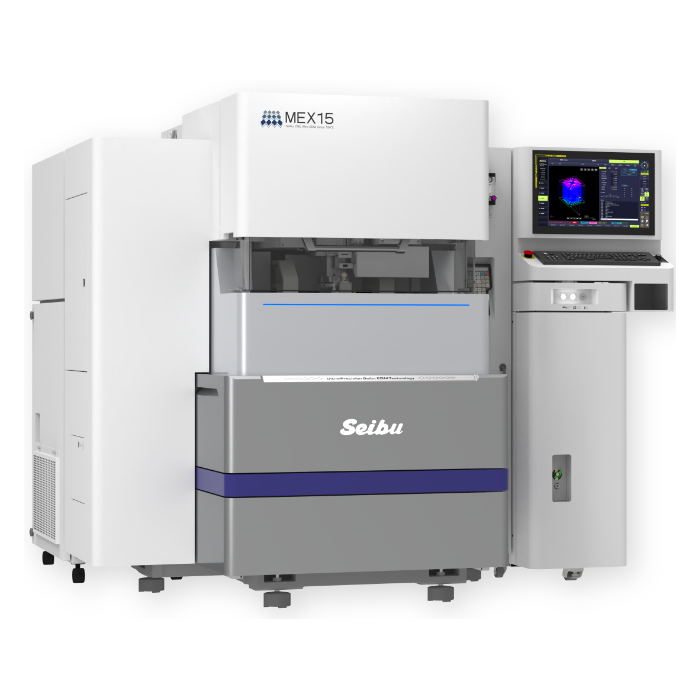

The pinnacle of

technology achieved in pursuit of high

precision Seibu Electric's

highest performance machine in history

150×150

highest performance machine in history

| Standard Specifications | MEX15 |

|---|---|

| Max. workpiece dimensions W×D×H |

180×165×60mm |

| Max. workpiece weight | 12kg |

| Axis travel range X×Y×Z |

150×150×120mm |

| U-V axis travel U×V |

±20× ±20mm |

| Max. taper angle | ±10°/work Thickness 60mm Conical cutting |

| Dimensions W×D×H |

1,830×1,770×1,855mm |

| Weight | 3,250kg |

| Control device | Smart NC |

|---|---|

| Input system | MDI, Ethernet, USB |

| Display | 21.5 inch TFT multi-touch screen |

| Axis controlled | 5 axis (simultaneously 4 axis) |

| Least input increment | 0.01µm |

| Least command increment | 0.01µm |

| Program memory capacity | 1GB |

| Power Supply | MPSC-20 |

|---|---|

| Input power source | 3-phase 200V/220V±10% 11 kVA, 50/60Hz |

| Weight | 160kg |

| Filtration device | MF300 |

|---|---|

| Tank capacity | 300L |

| Filter element | Paper filters (internal-pressure type)×2 |

| Deionizer | Oil spec./Oil(Class 4 Petroleum No.3) Water spec./Ion-exchanged water |

| Weight | 400kg |

Wire diameter : Φ0.03mm to Φ0.15mm

(Φ0.10mm is standard.)

※Should not exceed the max.

workpiece weight.

※Including

the weight of jig or the like

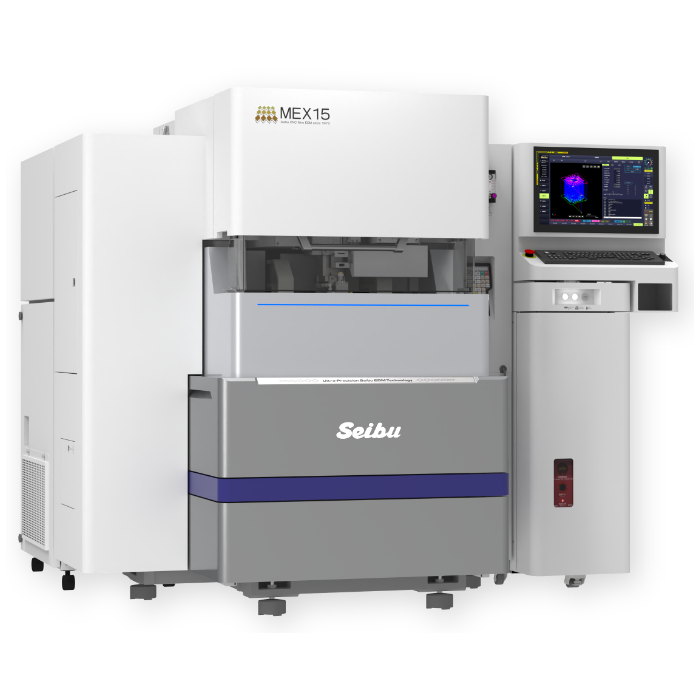

Oil Specification Wire EDM

The pinnacle of

technology achieved in pursuit of high

precision Seibu Electric's

highest performance machine in history

150×150

| Standard Specifications | MEX15 |

|---|---|

| Max. workpiece dimensions W×D×H |

180×165×60mm |

| Max. workpiece weight | 12kg |

| Axis travel range X×Y×Z |

150×150×120mm |

| U-V axis travel U×V |

±20× ±20mm |

| Max. taper angle | ±10°/work Thickness 60mm Conical cutting |

| Dimensions W×D×H |

1,830×1,770×1,855mm |

| Weight | 3,250kg |

| Control device | Smart NC |

|---|---|

| Input system | MDI, Ethernet, USB |

| Display | 21.5 inch TFT multi-touch screen |

| Axis controlled | 5 axis (simultaneously 4 axis) |

| Least input increment | 0.01µm |

| Least command increment | 0.01µm |

| Program memory capacity | 1GB |

| Power Supply | MPSC-20 |

|---|---|

| Input power source | 3-phase 200V/220V±10% 11 kVA, 50/60Hz |

| Weight | 160kg |

| Filtration device | MF300 |

|---|---|

| Tank capacity | 300L |

| Filter element | 4 Paper filters (internal-pressure type)×2 |

| Deionizer | Oil spec./Oil(Class 4 Petroleum No.3) Water spec./Ion-exchanged water |

| Weight | 400kg |

Wire diameter : Φ0.03mm to Φ0.15mm

(Φ0.15mm is standard.)

※Should not exceed the max. workpiece weight.

※Including the weight of jig or the like

The world of ultra-precision: Cutting to within ±1 µm

250×250

| Standard Specifications | M25LP |

|---|---|

| Max. workpiece dimensions W×D×H |

270×270×100mm |

| Max. workpiece weight | 150kg |

| Axis travel range X×Y×Z |

250×250×200mm |

| U-V axis travel U×V |

±35× ±35mm |

| Max. taper angle | ±10°/ 100mm |

| Dimensions W×D×H |

1,770×2,040×2,018mm |

| Weight | 3,100kg |

| Control device | Smart NC |

|---|---|

| Input system | MDI, Ethernet, USB |

| Display | 21.5 inch TFT multi-touch screen |

| Axis controlled | 5 axis (simultaneously 4 axis) |

| Least input increment | 0.01µm |

| Least command increment | 0.01µm |

| Program memory capacity | 1GB |

| Power Supply | MPSC-20 |

|---|---|

| Input power source | 3-phase 200V/220V±10% 11 kVA, 50/60Hz |

| Weight | 160kg |

| Filtration device | MF330 |

|---|---|

| Tank capacity | 330L |

| Filter element | 4 paper filters (internal-pressure type)×2 |

Wire diameter : Φ0.05 to Φ0.20mm

(Φ0.20mm is Standard.)