TASK REDUCTION

Advanced Wire EDM Automation and Task Control

function SSV

Seibu Scope Vision®Option

Operating interface with easy-to-see

graphics with a smartphone feel

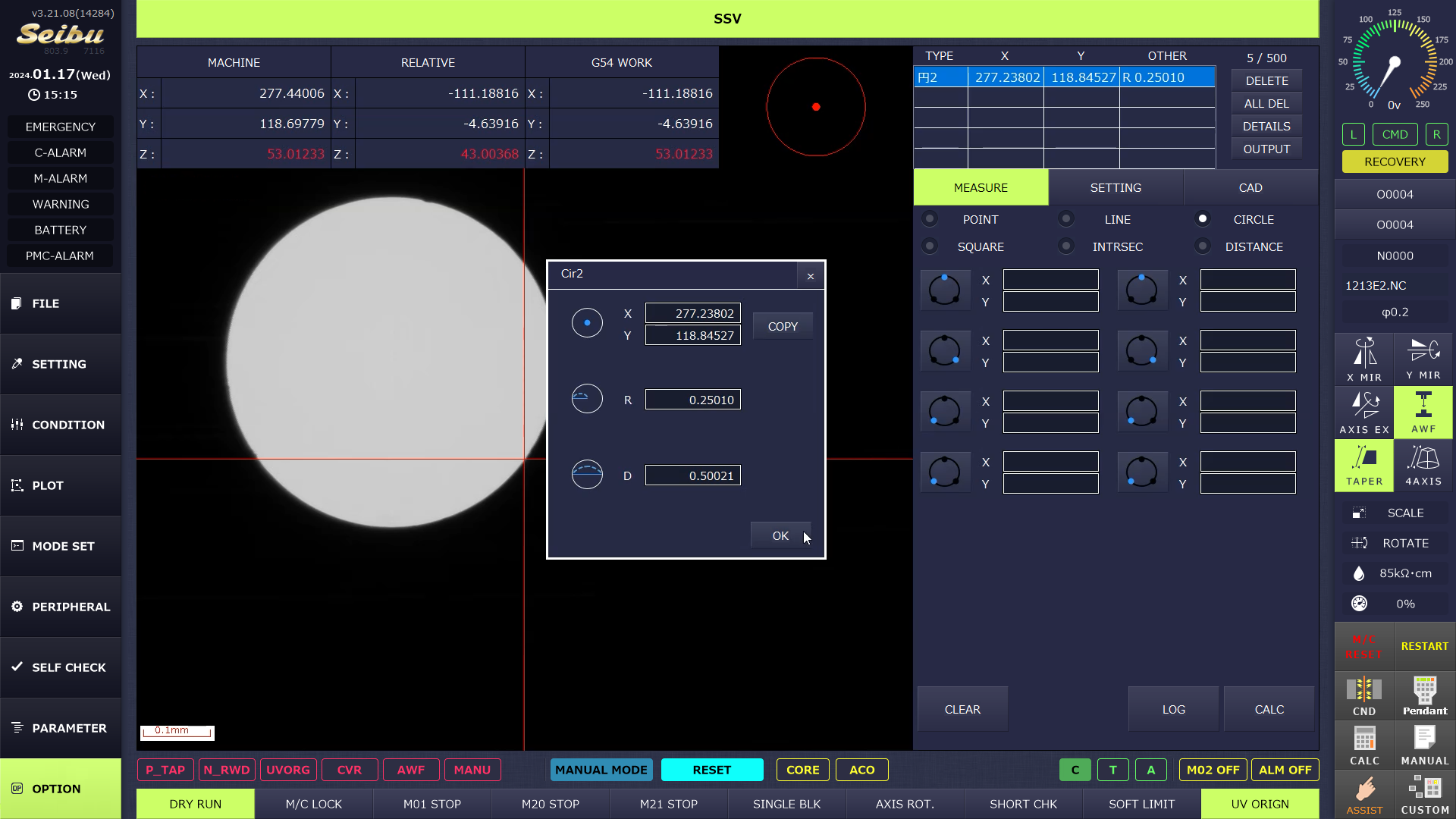

High-precision vision measurement with a camera is

possible on the machine without removing the

workpiece after cutting is completed.

A wide variety of measurement options are available

for measuring various shapes.

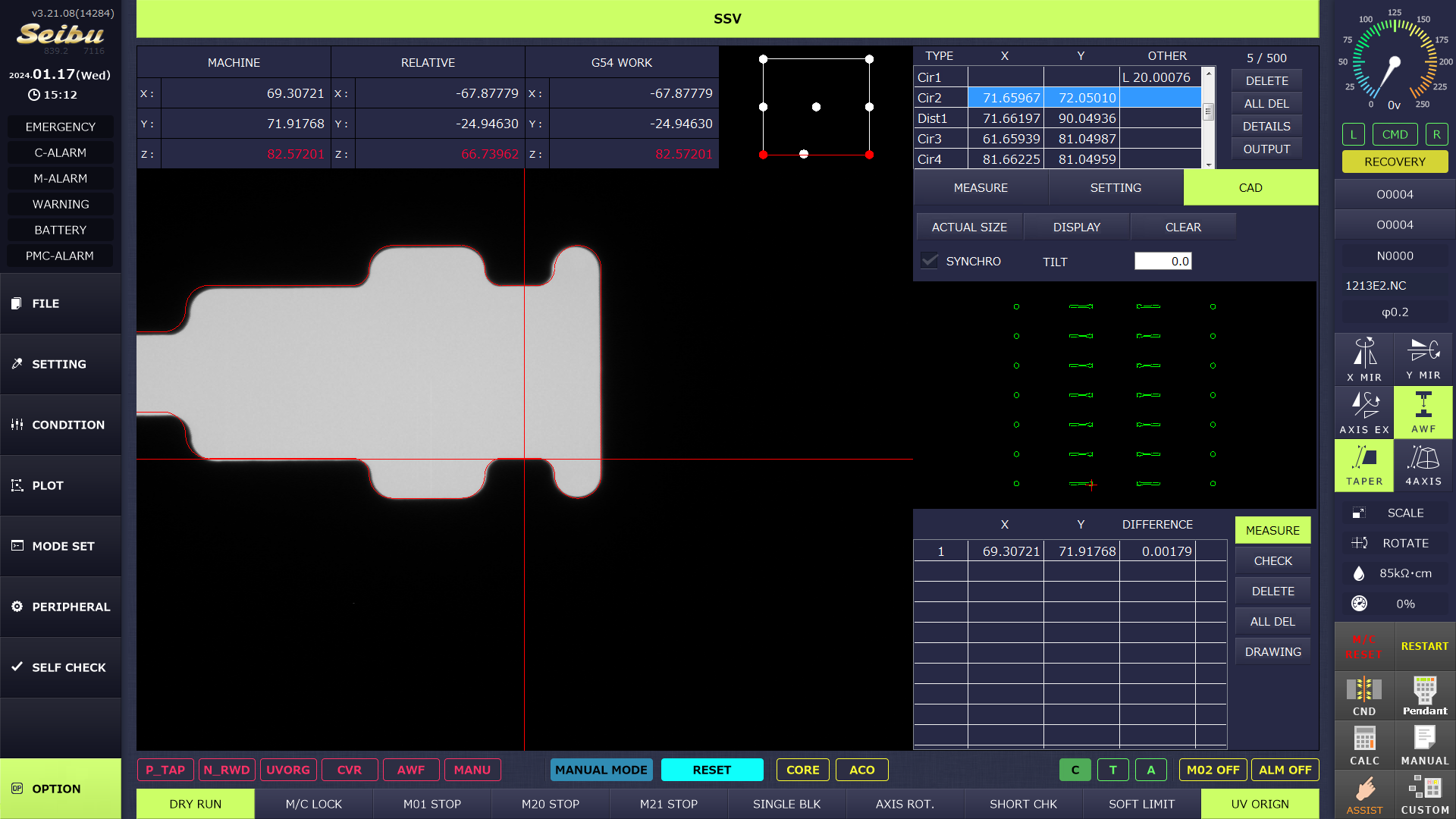

It is also possible to check the CAD data and the

machined shape and perform the difference

measurement.

Specifications

monitor magnification approx.

100×

(at maximum zoom factor)

(simultaneous lighting)

function

movement possible)

(2.60×2.60×2.76inch)

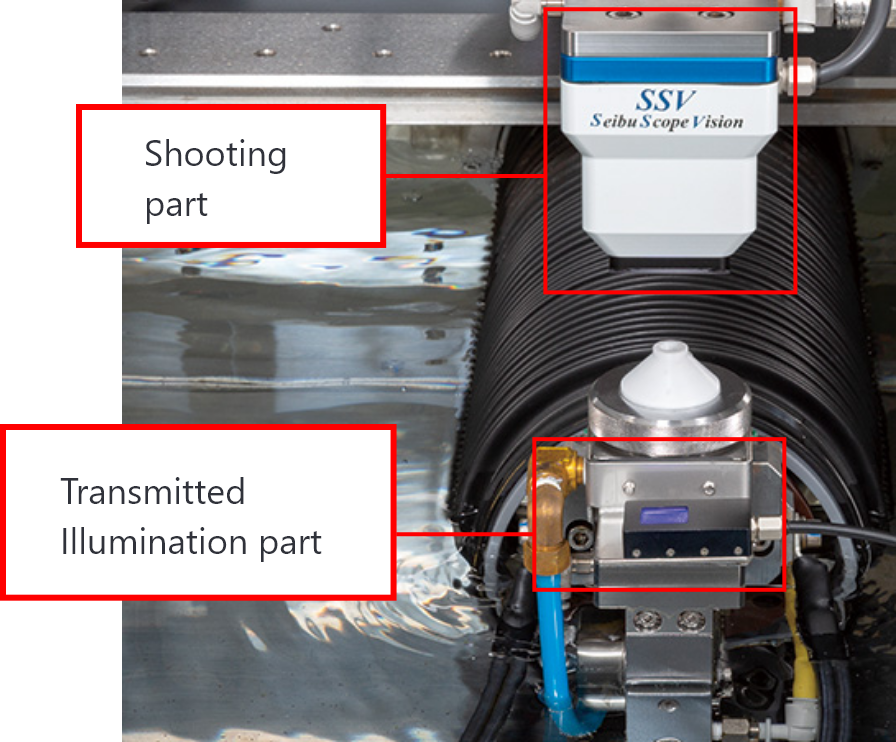

「SSV Mounting」

• CAD drawings (DXF) can be read for contour verification and difference measurement

• Available in a wide variety of measure options for measuring various machined workpieces

• High-precision edge detection with transmitted illumination

• Can be measured without removing the workpiece after cutting

• High-precision measurement of fine shapes

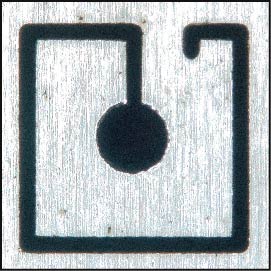

Circle measurement screen

CAD verification screen

Core Stitch®Option

Greatly improved automation efficiency

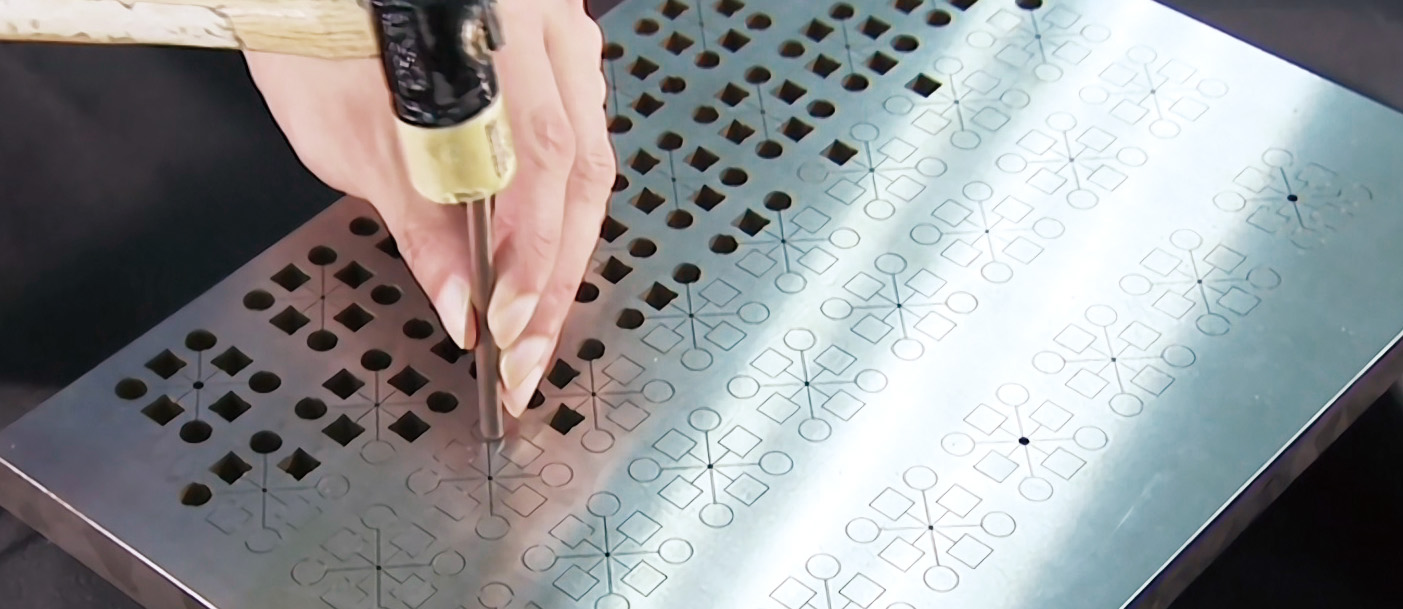

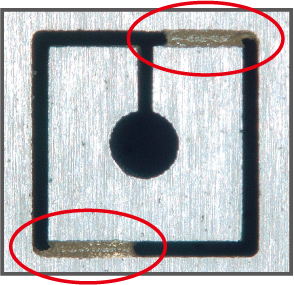

Since the brass can be welded on the part 1 mm(0.039

inch) from the upper face,

it is possible to knock out the welded part by

tapping on the slugs.

Conventional cut-off

Core Stitch

• Simple task by only tapping on the core

• Simplification of NC program (Programming for cut-off part is not necessary.)

• You can solve the conventional problems quickly.

(e.g. man-hour reduction, mistake prevention, relief of simple task)

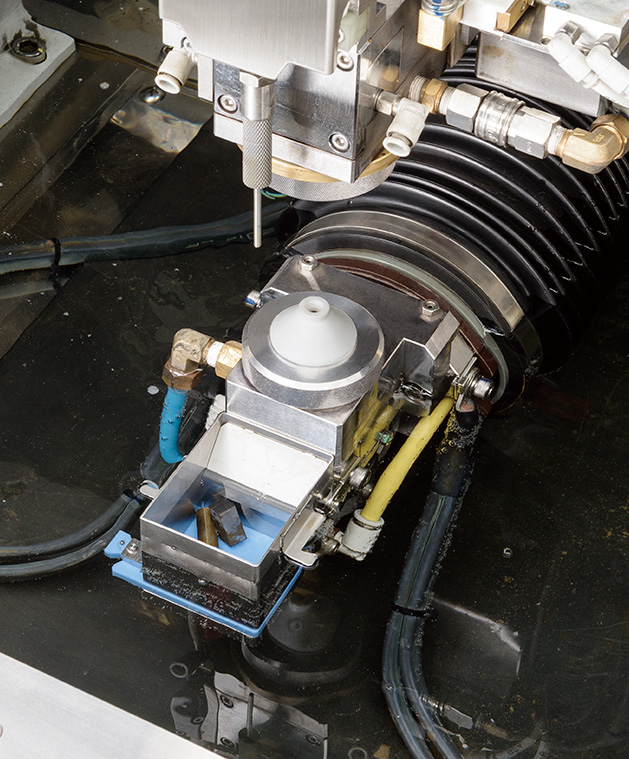

Core CatchOption

Core Catch enables you to process welded

core automatically.

The hammer mounted on upper head knocks

off the core made after Core Stitch cutting

and the core can be automatically collected.

This fully automated process realizes

unmanned operation for die plate finish cut.

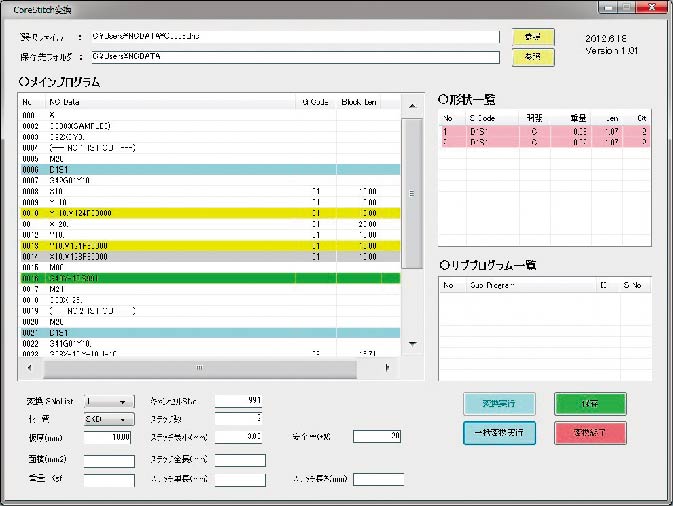

Core Stitch conversion softwareOption

This is software for PC that optimizes the welding point and distance by analyzing NC programs and automatically inserts core stitch codes into NC programs.

High Rigidity Mechanical Structure

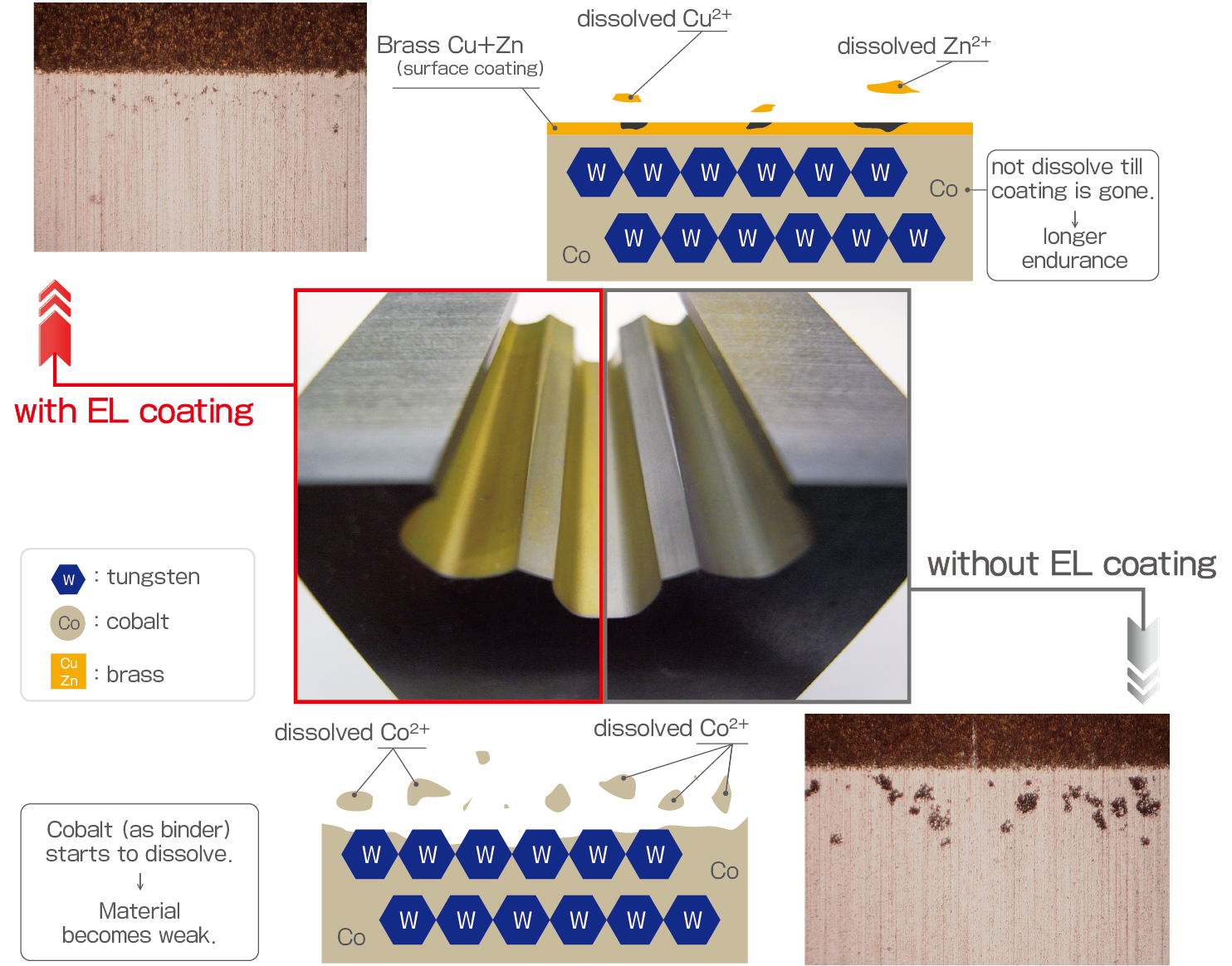

Measure against tungsten corrosion

EL coating is unique technology that prevents cobalt (Co) from dissolving in water by means

of coating

the cutting surface with brass. This increases the endurance of the mold.

This makes it possible to cut in water (not in oil), which reduces maintenance work.

When tungsten carbide material is cut in water, the cobalt (as binder) starts to dissolve in

water.

As a result, the material becomes weak.

EL Coating

Cutting surface is coated with thin brass layer.

• Anti-corrosion is possible in water.

• Compared with cutting in oil, maintenance work is very easy.

• Endurance of mold is equal to mold produced in oil.