RELIABLE FEEDING TECHNOLOGY

Reliable EDM Wire Feed System

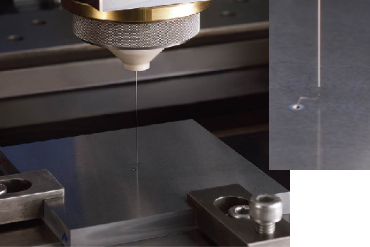

Thin wire travel

Twin tension dancer roller

(SMM80B/MM75B/MM-UP Series)

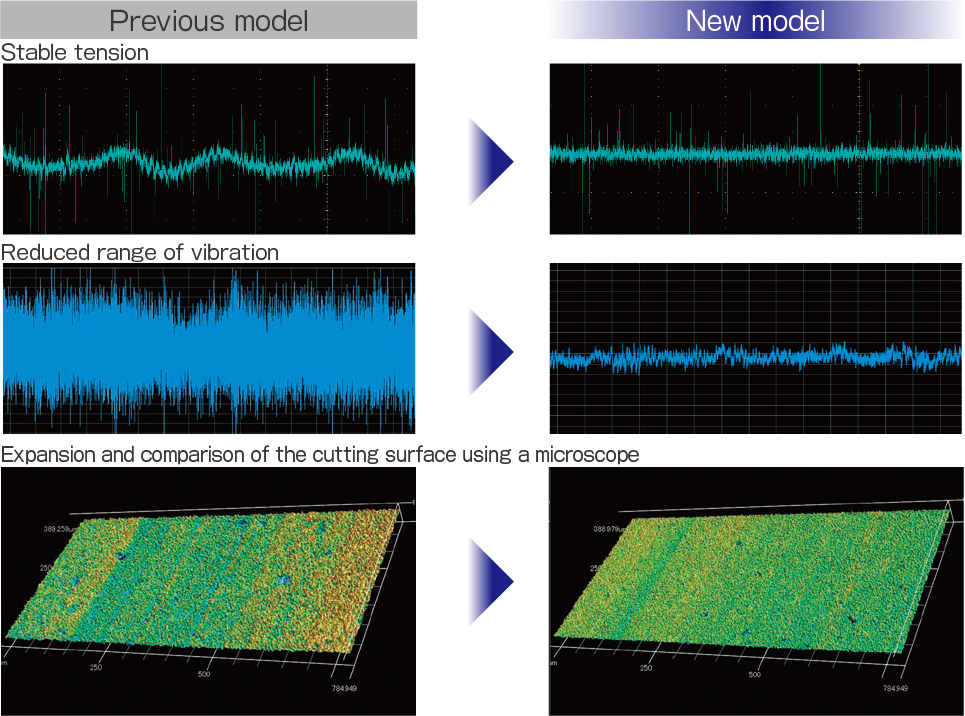

Through improvement in the wire tension system, we have achieved stable tension and reduced

vibration when the wire is traveling.

This has improved the cutting surface quality during finish cutting.

Automatic wire feeding device (AWF)

Greatly improved automation efficiency

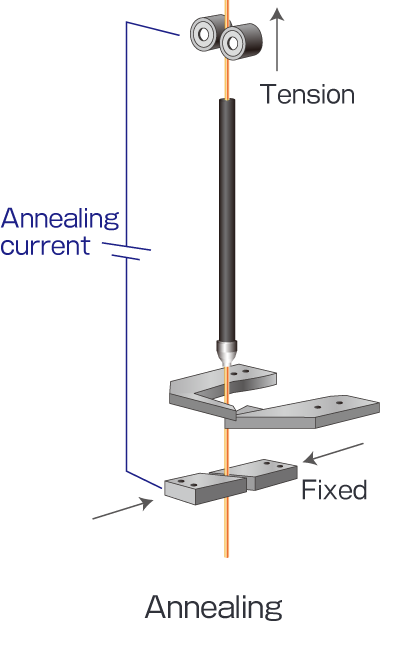

We have used the anneal dry method consistently since 1981.

In recent years, we developed functionality that allows annealing in a fixed position without

rotating the rollers.

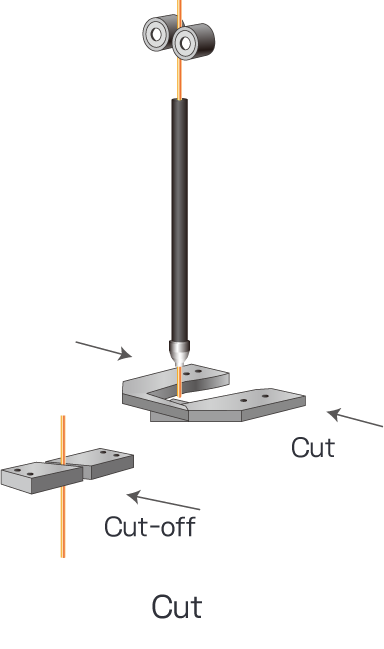

We are continuing advances that increase the wire feeding rate. This feature is essential for

increasing

the utilization rate and for automation of Wire EDM.

Automatic wire feeding (AWF)

横スクロールでご覧いただけます。

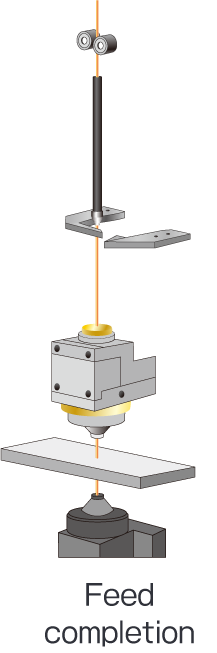

All-in-one AWF

Feed at wire break point

Using Seibu's patented "Friction sensor" technology,

the wire can thread reliably through a start hole

or slot.(PATENTED)

Friction sensor

Wire can be reliably threaded even at the break point.

This is an essential function for core stitch cutting.

Friction Sensor Wire Feeding System

Wire feeding in water

It is possible to thread wire in water,

through slot due to anneal dry method.

Thin wire feeding

It contributes to the automatization of

microfabrication.

Skip figure function

Automatic operation can continue

without stopping even at an

unexpected trouble.

Various functions

Reliable feeding to difficult workpiece

It is possible to feed automatically through the slit of comb-shaped workpiece with annealing and friction sensor.

Round diamond die guide

A Round guide is used that focuses on cutting accuracy.

(Common to the upperand lower guides)

Jet feed guideOption

Water jet (option) is flushed from upper head nozzle to enhance the success rate of

feeding.

(Guides are not common to upper and lower guide.)