Zero-Tolerance Wire EDM Machining Precision

Ultra-precision Plate Cutting

Mold production without jig grinding

process

(MM50UP: cutting example)

Inserting the pins into three plates separately cut

with different thickness

T20,22,25mm(T0.79,0.87,0.98inch)

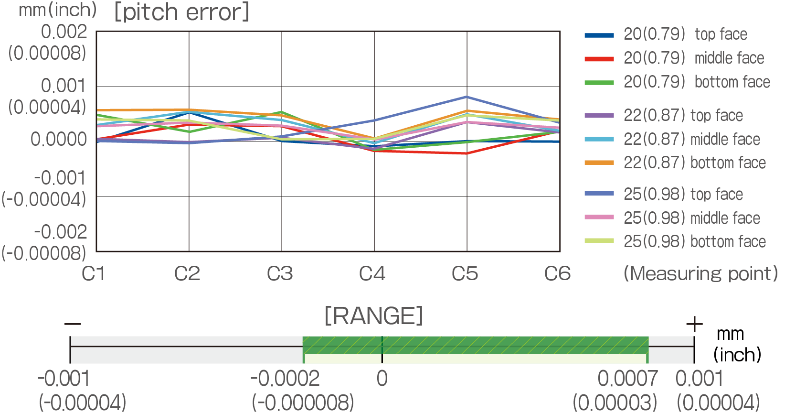

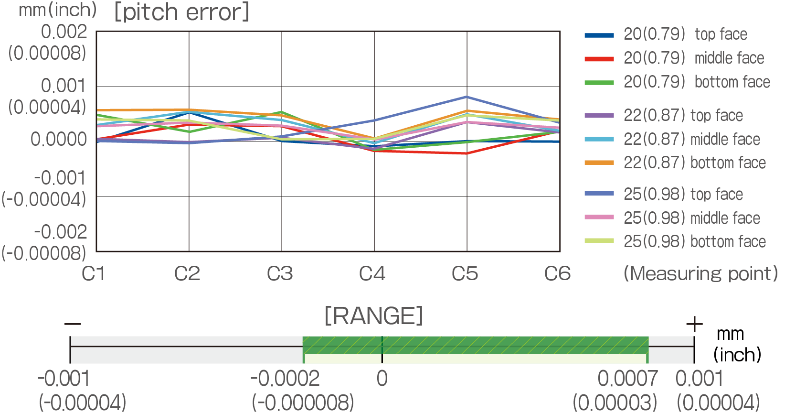

Plate cutting pitch accuracy

Thickness

: 20,22,25mm

(0.79,0.87,0.98inch)

Number of cuts

: 6 Passes

Wire diameter

: Φ0.2mm(0.008inch)

X axis pitch error

Error range

0.0014mm(0.000055inch)

Y axis pitch error

Error range

0.0010mm(0.000039inch)

Cutting Samples

mm(inch)

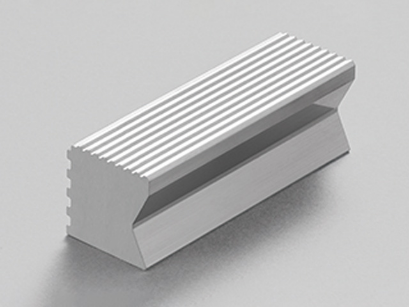

Combination cutting

Material: D2

Thickness: 60(2.36)

Cutting time: 50 hours

Wire diameter: Φ0.2(Φ0.008)

Surface finish : Ra 0.25µ(10µ)

Rz 2.00µ(12.3µ)

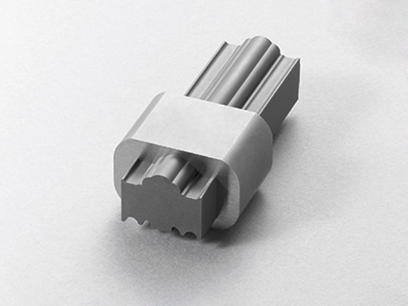

High-precision step combination cutting

Material: D2

Thickness:60,80(2.36,3.15)

Cutting time: 7.3hours

Wire diameter: Φ0.25(Φ0.010)

Surface finish : Ra 0.25µm(10µ)

Rz 2.00µm(12.3µ)

Dimension accuracy: ±2µ(±0.00008)

Best surface finish

Material: D2

Thickness: 30(1.18)

Cutting time: 3 hours

Wire diameter: Φ0.1(Φ0.004)

Surface finish : Ra 0.06µm(2.4µ)

Rz 0.50µ(3.08µ)

Tall thickness taper combination cut

Material: D2

Thickness:100(3.94)

Cutting time: 4 hours

Wire diameter: Φ0.25(Φ0.010)

Surface finish : Ra 0.30µ(12µ)

Rz 2.80µ(17.2µ)

Taper angle: 10°

Large angle 45 taper cut

Material: D2

Thickness:40(1.58)

Cutting time: 5.0 hours

Wire diameter: Φ0.2(Φ0.008)Megacut-T

Surface finish : Ra 0.5µ(20µ)

Rz 4.50µ(27.7µ)

Best surface finish

Material: D2

Thickness: 30(1.18)

Cutting time: 4.3 hours

Wire diameter: Φ0.20(Φ0.008)

Surface finish : Ra 0.08µ(3.2µ)

Rz 0.65µ(4µ)

Dimension accuracy: ±2µ(±0.00008)

Full circumference cutting of

small-diameter gears

Material: WC(RG3)

Thickness: 3(0.118)

Cutting time: 1.5 hours

Wire diameter: Φ0.10(Φ0.004)

Surface finish : Ra 0.28µ(11.2µ)

Rz 2.28µ(14µ)

Dimension accuracy: ±2µ(±0.00008)

High-thickness fit cutting

Material: D2

Thickness:200(7.87)

Cutting time: 21 hours(Total)

Wire diameter: Φ0.25(Φ0.010)

Surface finish : Ra 0.55µ(22µ)

Rz 4.41µm(27.1µ)

Dimension accuracy: ±2µm(±0.00008)

Tall thickness cut

Material: D2

Thickness:120mm(4.72)

Cutting time: 3.5 hours

Wire diameter: Φ0.2(Φ0.008)

Surface finish : Ra 0.31µ(12.4µ)

Rz 2.50µ(15.4µ)

Dimension accuracy(inch)

|

Height |

surface1 |

surface2 |

| Top |

4.72

3.54 |

0.78740

0.78736 |

0.78736

0.78737 |

| Middle |

2.36

1.18 |

0.78740

0.78741 |

0.78739

0.78740 |

| Top |

0 |

0.78742 |

0.78741 |

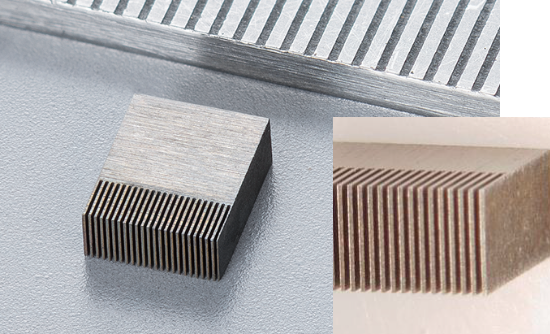

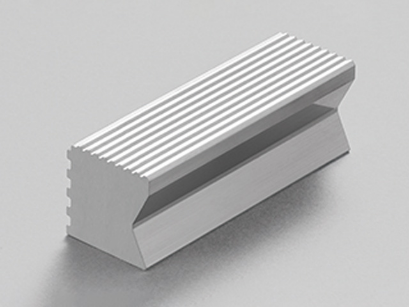

Serration cutting (die / punch)

Die

Material: D2

Thickness: 20(0.787)

Cutting time: 3.8h

Wire diameter: Φ0.10(Φ0.004)

Surface finish : Ra 0.15µ(6µ)

Rz 1.21µ(7.44µ)

Dimension accuracy: ±2µm(±0.00008)

Punch

Material: WC(RG3)

Thickness: 60(2.26)

Cutting time: 8.2 hours

Wire diameter: Φ0.10(Φ0.004), Φ0.25(Φ0.010)

Surface finish : Ra 0.12µ(4.72µ)

Rz 0.98µ(38.6µ)

Dimension accuracy: ±2µ(±0.00008)

Cutting Sample

Cutting by Water type machine

Leadframe cutting

Material: D2

Thickness: 3(0.12)

Cutting time: 1 hours

Wire diameter: Φ0.03(Φ0.0012)

Surface finish : Ra 0.10µ(3.94µ)

Rz 0.90µ(5.5µ)

Number of cuts: 5th

Shape accuracy

±1.0μm(0.00004)

Cutting by Oil type machine

Comb cutting

Material: WC

Thickness: 1(0.04)

Cutting time: 4 hours

Wire diameter: Φ0.03(Φ0.0012)

Surface finish : Ra 0.10µ(3.94µ)

Rz 0.91µm(5.6µ)

Number of cuts: 5th

Shape accuracy

±2.0μ(0.000078)

Ultra-fine processing

Material: WC

Thickness: 1(0.04)

Cutting time: 4 hours 35minutes

Wire diameter: Φ0.03(Φ0.0012)

Surface finish : Ra 0.10µ(3.94µ)

Rz 0.90µ(5.5µ)

Number of cuts: 4th

Shape accuracy

±1.5μm(0.000059)

● The data listed in the sample is the result of our test conditions using tungsten

wire, and is different from the guaranteed accuracy.