ALWAYS ACCURATE

High-Accuracy Wire EDM Machining Performance

Increased cutting accuracy

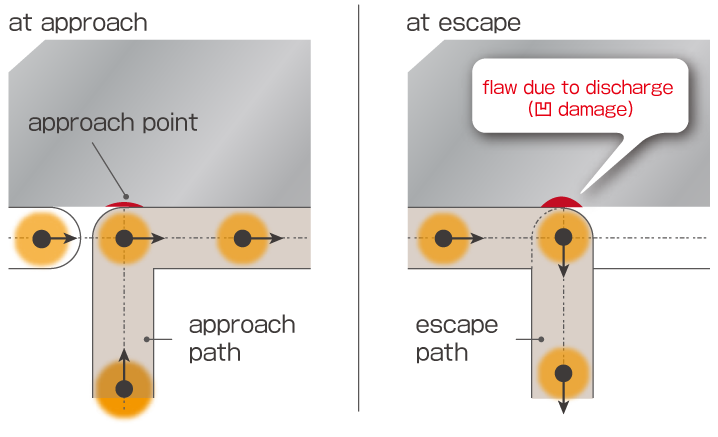

Function of reducing flaw of approach

In general cutting,

the discharge flaw was caused by passing

two

approach points (at approach and at escape).

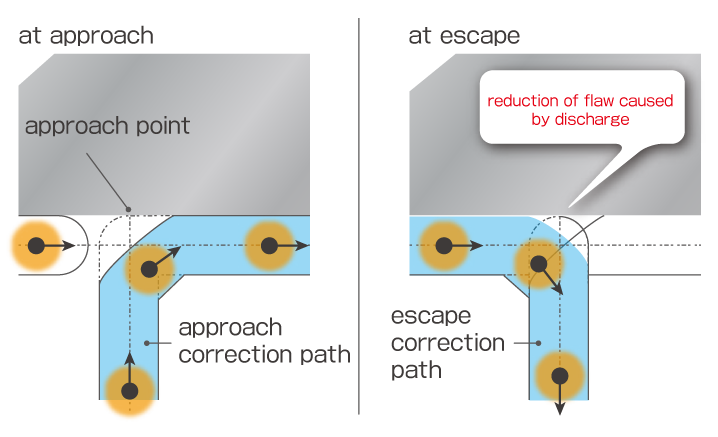

It is possible to reduce the flaw of approach part

by correcting the path of both

approach and escape.

For other correction function,

corner shape correction and taper cut

correction are available.

Normal cutting

Function of reducing flaw of approach

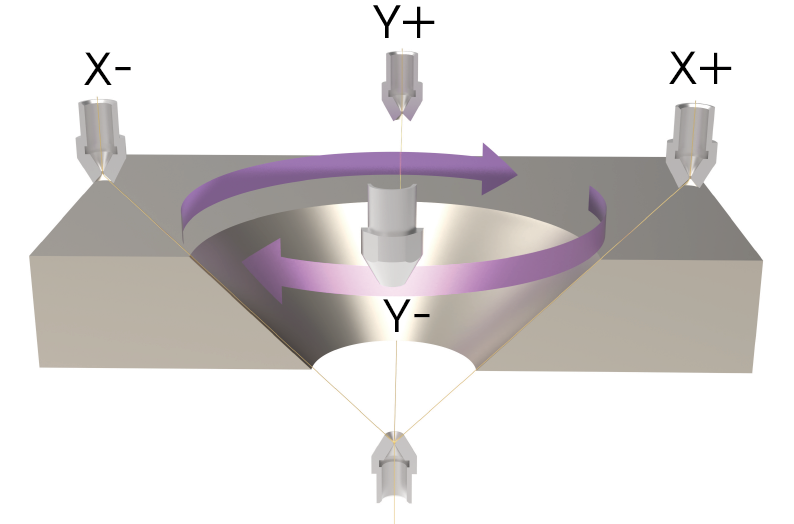

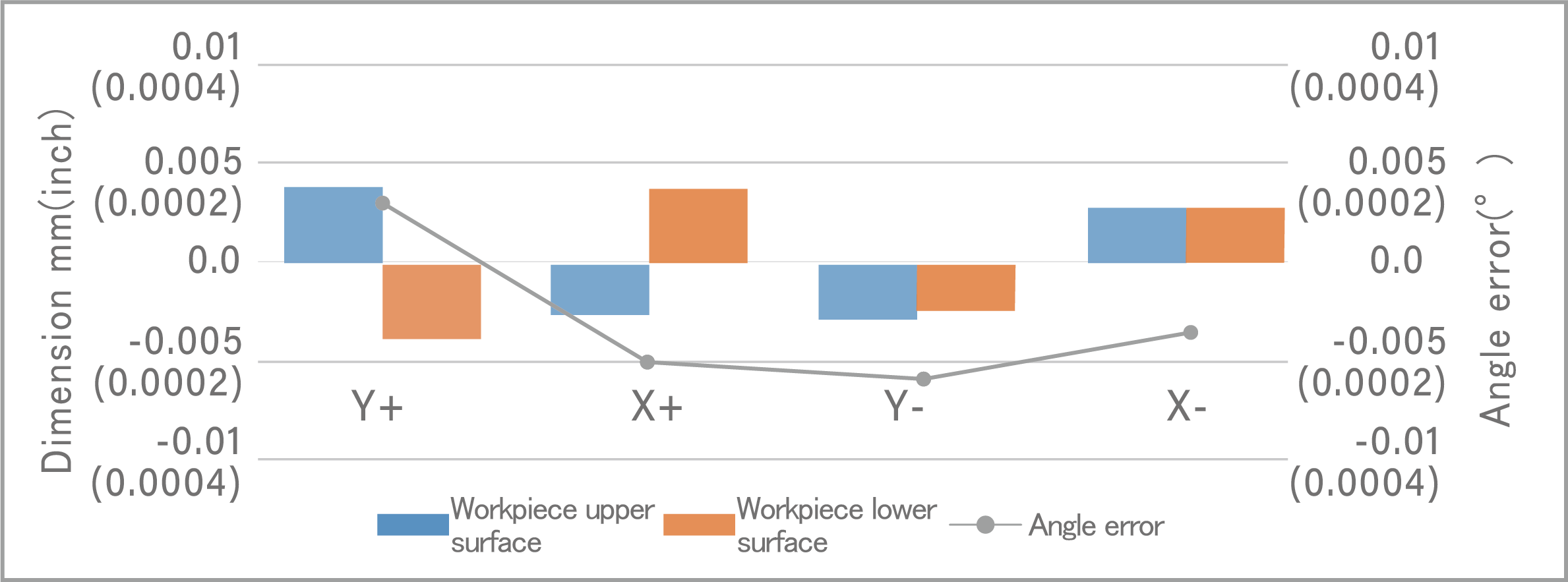

Feature for increasing taper

cutting accuracy

We have developed a feature that can recalculate the taper dimensions

from the results of test cutting, and simultaneously correct the angle and

dimension accuracy.

We have greatly increased the taper angle accuracy and dimension accuracy.

We have developed a feature that can recalculate the taper dimensions

from the results of test cutting, and simultaneously correct the angle and

dimension accuracy.

We have greatly increased the taper angle accuracy and dimension accuracy.

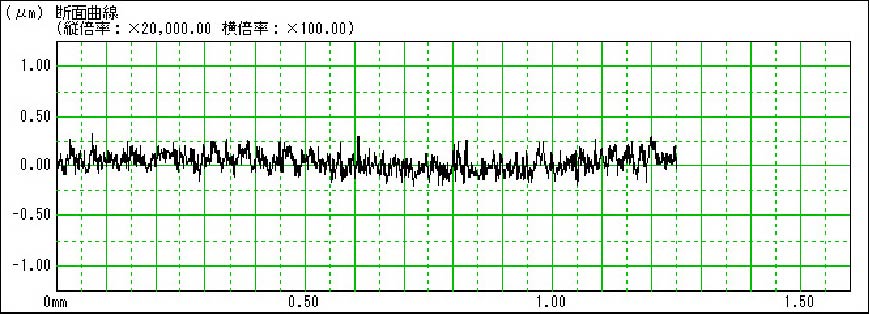

Best surface finish / Improvement of cutting surface finish

The effect of the insulation table enables stable output of micro current pulses,

resulting in improved surface finish, shorter finishing stroke, and shorter total cutting

time.

Especially we could achieve under Rz 0.5µm with steel.

(10.6µinch)

(12.9µinch)

(2.56µinch)

(2.76µinch)

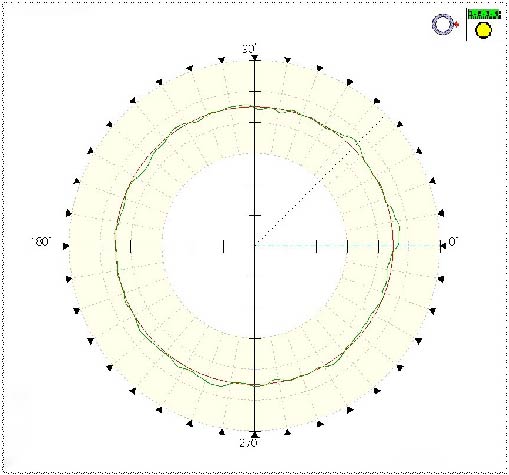

Roundness

Straightness of XY axis has been improved and achieved roundness 0.81µm by stable table feed.

Roundness

1.32µm(0.00005inch)