EASY SET-UP

Easy Setup for Efficient EDM Machining

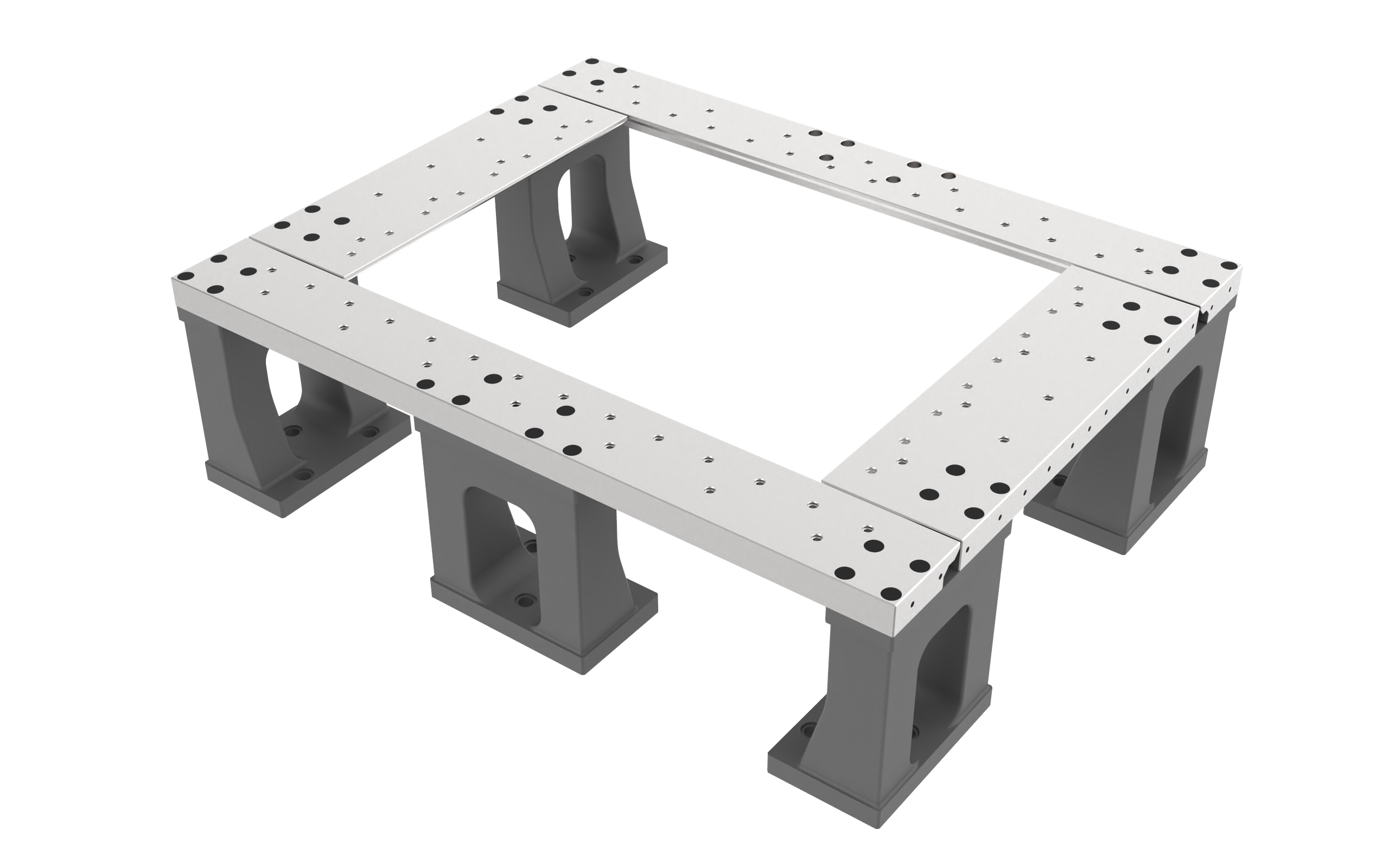

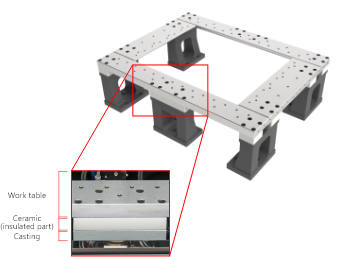

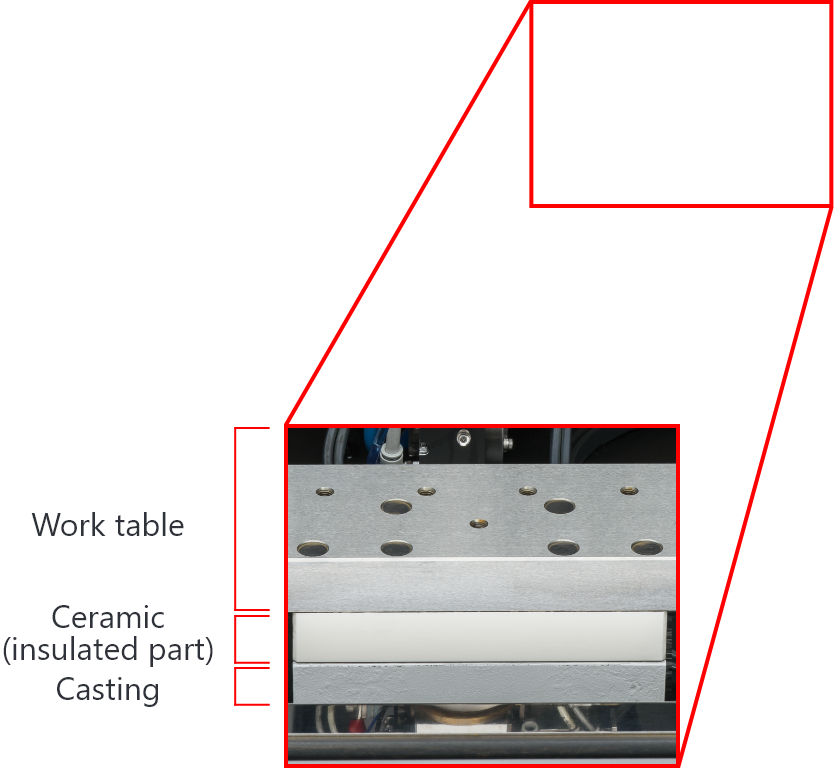

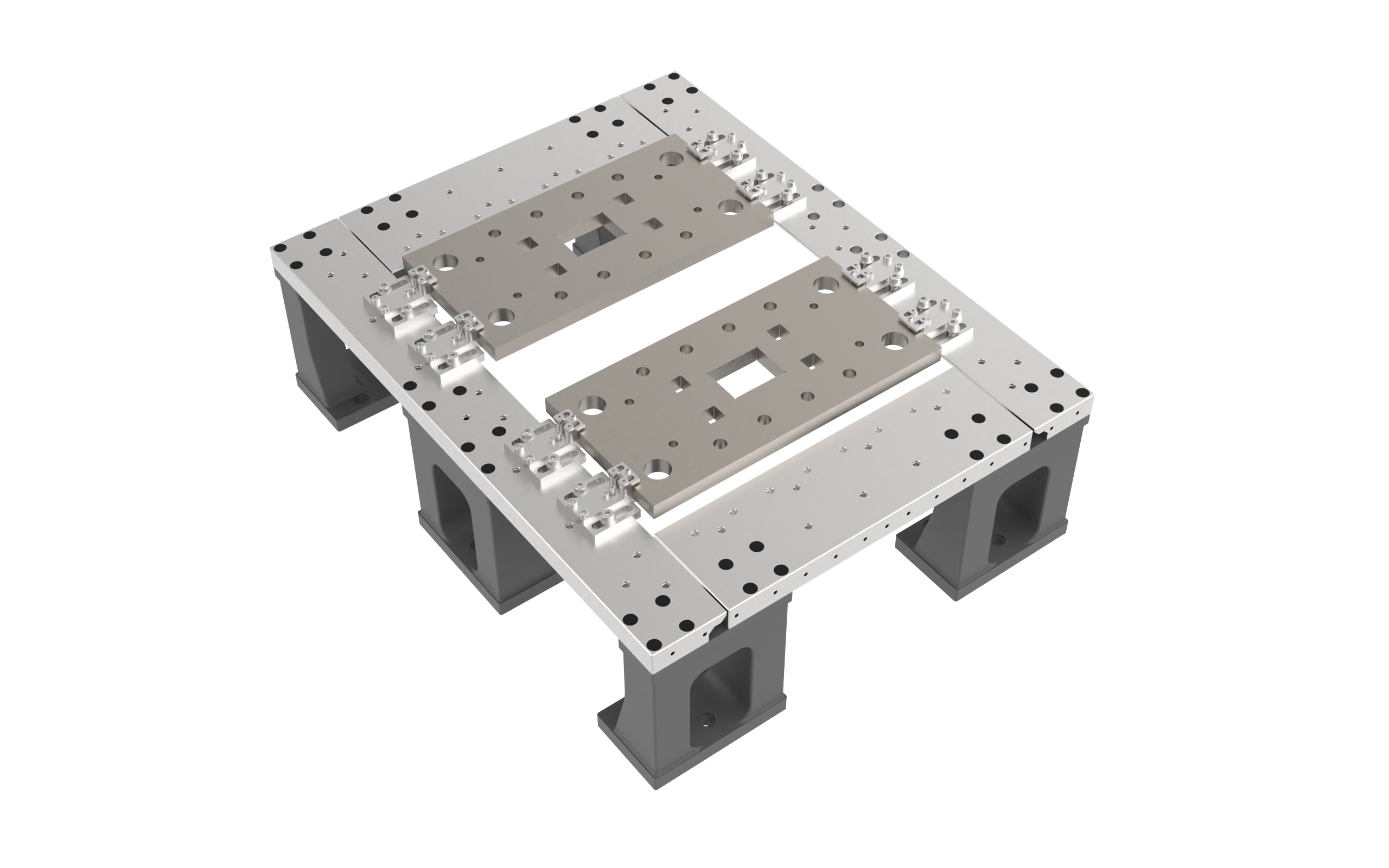

Newly Designed Work Table

Square tables equipped as standard

(Not applicable to M-HP series.)

All models are equipped with square-type work table as standard.

Since workpiece set-up is possible at the back of the table, workability can be improved.

Work table insulation specification is available for MMUP series only.

M - HP

MM - UP

*The back of the table is just for support.

The accuracy of top surface flatness is not guaranteed.

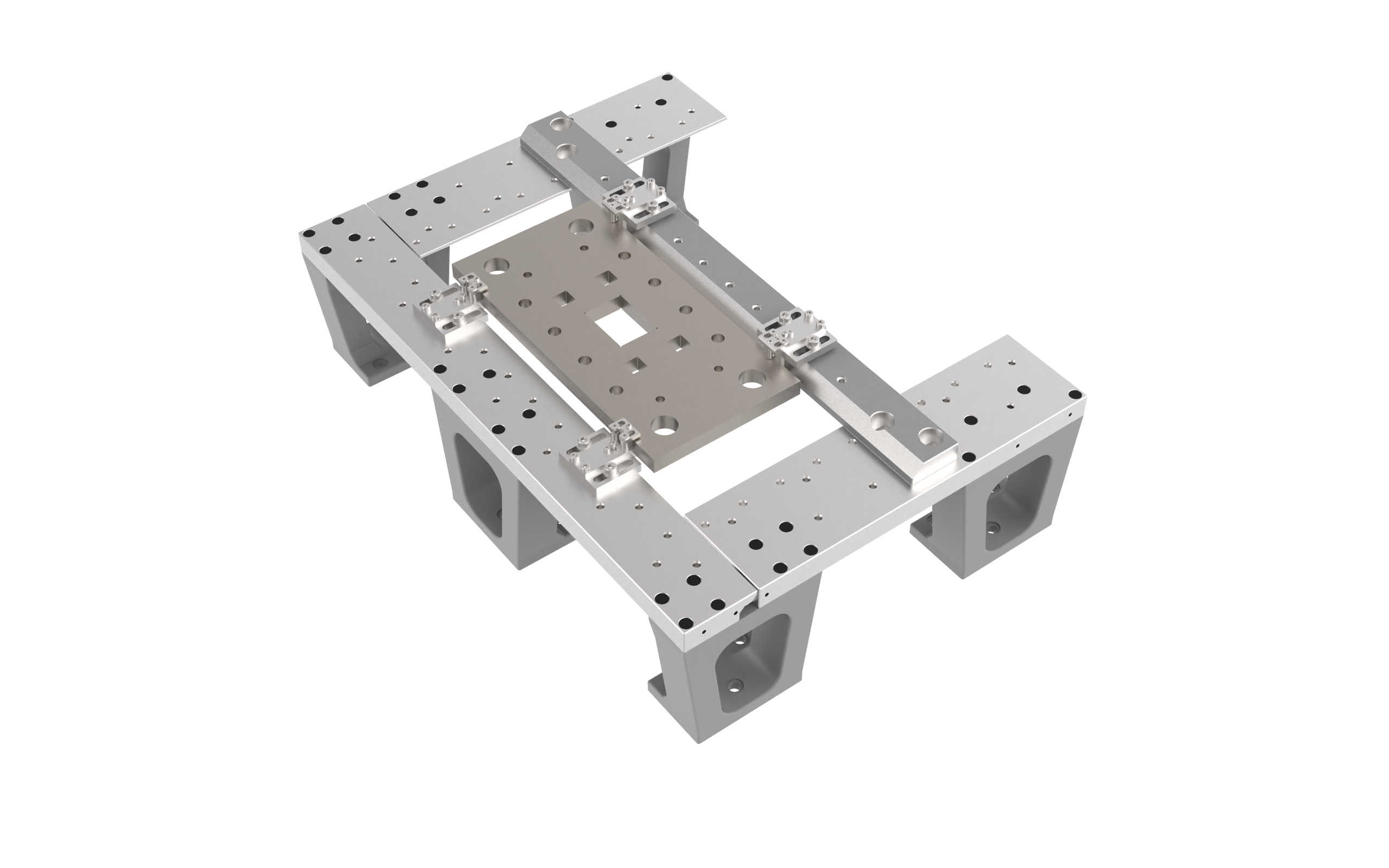

Y-axis stroke extension

Y axis stroke has been extended by 50 mm(1.97 inch)

to expand the cutting

range.

By setting two plates,

whereas only one plate could be set in the past,

which contributes to productivity improvement.

Previous model

New model

*The back of the extension is just for support.

The accuracy of top surface flatness is not guaranteed.

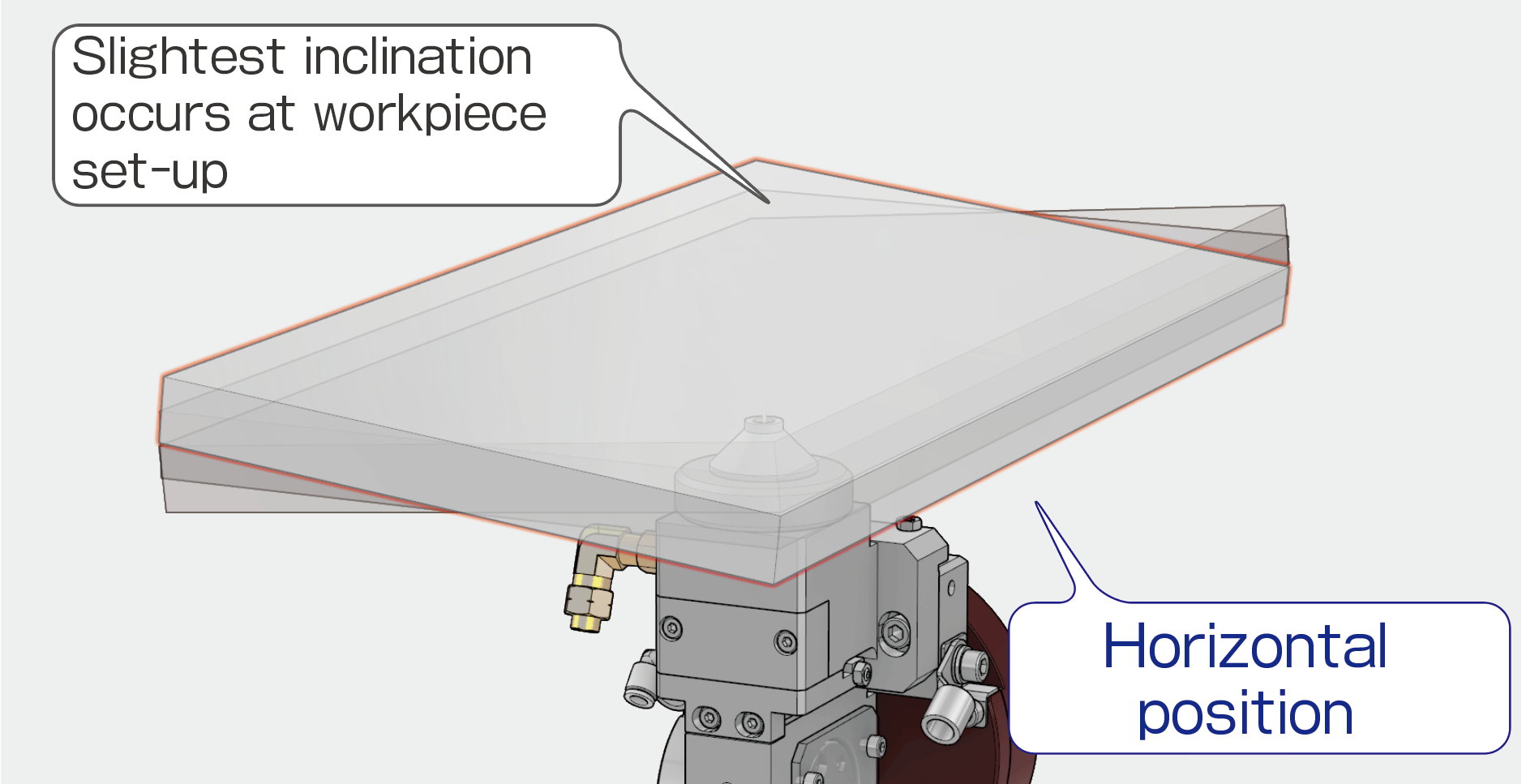

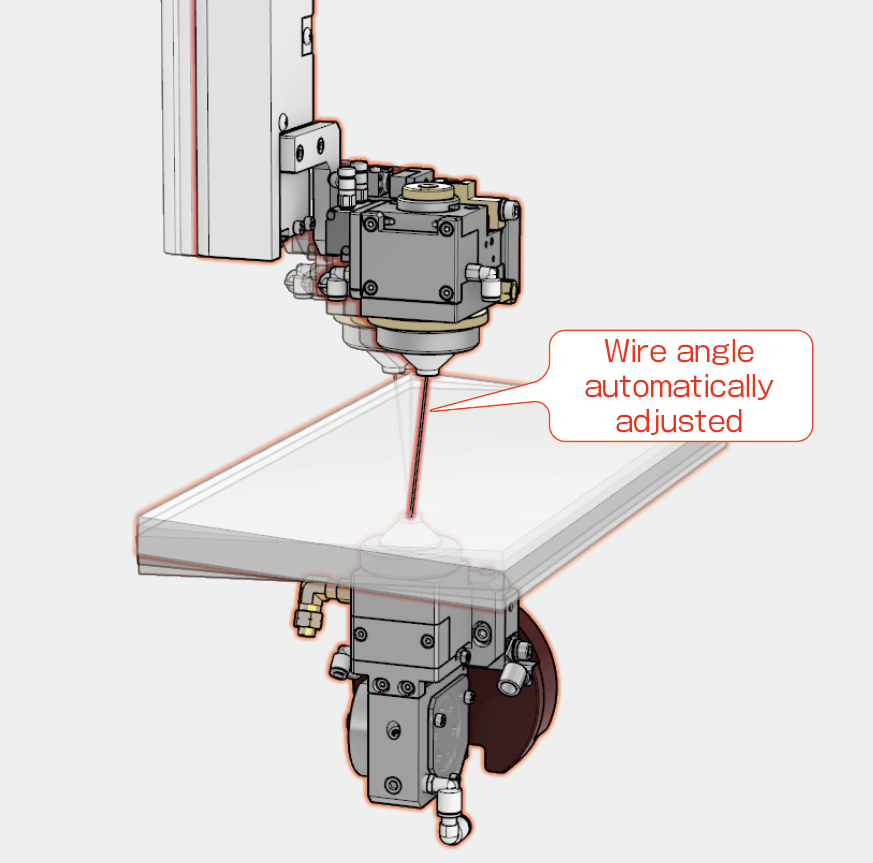

3D Level Adjust®Option

Automatic correction for vertical accuracy

Three points on the upper face of workpiece can be measured with high precision touch probe sensor mounted on the upper head. It is possible to adjust the wire alignment automatically with reference to the workpiece inclination to the work table. Spark positioning and horizontal adjustment jig becomes unnecessary due to this function, which reduces set-up time.

3D Level Adjust Plus

Shape measurement after cutting can be performed by adding software to this option.

1Slightest inclination occurs at workpiece set-up.

2Three points on the upper face of workpiece are measured with touch probe sensor and the inclination of workpiece is calculated.

3UV axis are automatically adjusted so that wire can become vertical to the workpiece.

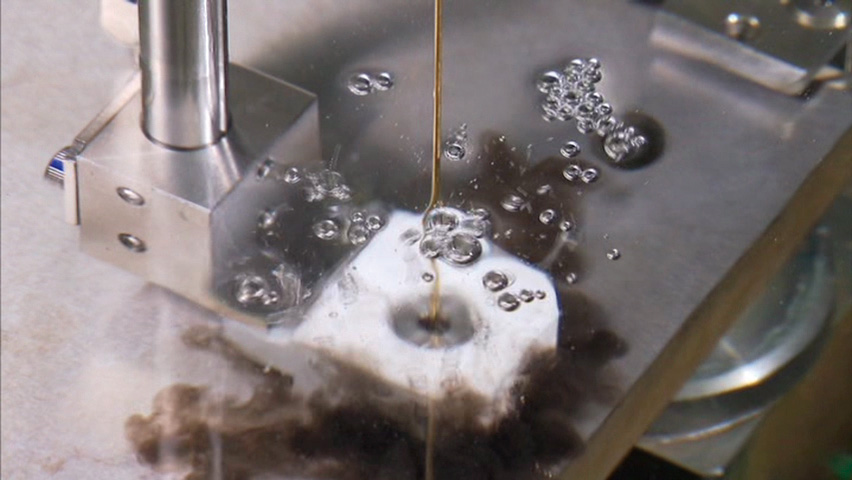

Start hole device®Option

SHM = Simple type start-hole cutting device

SHM2 is a start-hole drill that can be easily mounted on a machine.

Hole-drilling is possible for hardened workpiece or tungsten carbide (WC).

Start hole device(SHM2) mounting

• Standard Φ1.0mm(0.04inch) pipe electrode

• Max. workpiece thickness 60mm(2.36inch)

• Drilling speed 10mm/min (D2)

Start hole device (SHM2) is Seibu unique function.

● Applicable electrode diameter

Φ0.3(0.012),Φ0.5(0.02),Φ0.8(0.031),Φ1.0(0.039),Φ2.0(0.079),

Φ3.0(0.118)

Setting operation cutting

conditions can be easily

performedusing a dedicated

operation screen.

Dedicated screen

Start hole drilling

| D2 | WC | |||

|---|---|---|---|---|

| Electrode diameter | Maximum drilling height |

Average drilling speed |

Maximum drilling height |

Average drilling speed |

| mm(inch) | mm/min(inch) | mm(inch) | mm/min(inch) | |

| Φ3.0 | 60(2.36) | 5.0(0.197) | 40(1.57) | 1.5(0.059) |

| Φ2.0 | 60(2.36) | 7.0(0.276) | 40(1.57) | 3.0(0.118) |

| Φ1.0 | 60(2.36) | 10.0(0.394) | 40(1.57) | 4.0(0.157) |

| Φ0.8 | 40(1.57) | 4.0(0.157) | 20(0.787) | 2.5(0.0984) |

| Φ0.5 | 10(0.394) | 3.0(0.118) | 10(0.394) | 1.0(0.039) |

| Φ0.3 | 5(0.197) | 0.5(0.020) | 5(0.197) | 0.5(0.020) |

The maximum drilling height means the workpiece thuckness drillable with the electrode of 300mm(11.8 inch) length.